If you are interested in the variety of printing techniques offered to you form your professional printing company, you have come to the right place.

Here, we unpack some of the printing world’s most popular and affordable printing techniques. Consider some of these awesome options for your next printing job!

Silk Lamination/ Lamination

A silk lamination print gives your material a soft, silk-like finish. This finish also makes your paper stock water resistant and tear resistant. It is a popular finishing for materials with bright colours – the finish definitely makes colours pop!

So, how does this work?

For example: if you have a business card that you would like to make more durable and eye-catching, then silk lamination is a great option for you. Your business card would be traditionally printed in full colours but an additional step would then be taken to give your card stock a unique texture. Your paper stock will be coated with a weather resistant, water resistant, and durable silk laminate.

Silk laminate can be a liquid or a film – but both stick to the surface and protect it, giving it a muted or sheen effect. The effect you choose can be dull, glossy, or even satin!

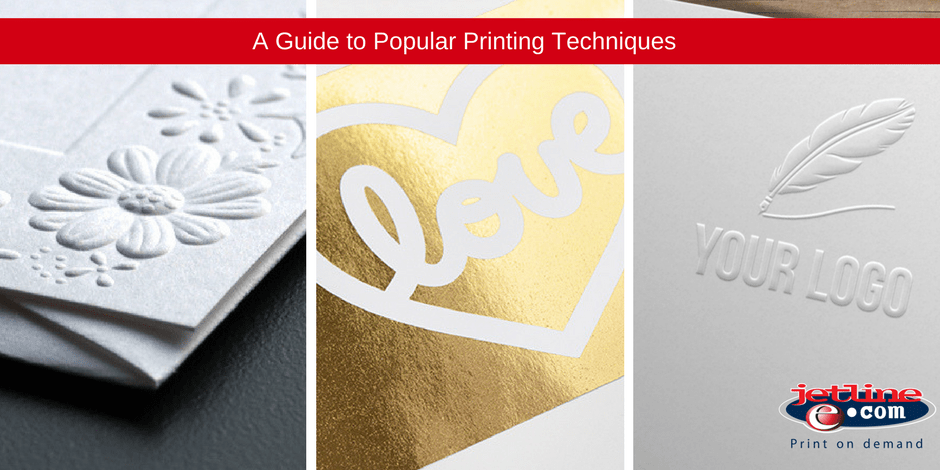

Embossing/ Debossing

The process of embossing and debossing are similar – but create very different results.

Both processes make use of a metal plate and a counter. The metal plate is mounted on a press and the paper stock is stamped between the counter and the plate. This pressure pushes the paper into the plate – creating the chosen impression.

Embossing creates a raised impression while debossing produces a de-pressed impression.

When designing for a print that includes either debossing or embossing, it is important to remember:

- Embossing is a technical and mechanical process that manipulates your paper stock – with this in mind, it will manipulate your design.

- Set your font with bigger spaces between the letters then you usually would. If you would place them too close to one another, they may merge and appear as a single element once the process has been completed.

- Embossing will make your design look smaller and reduce the sharpness of smaller designs.

Varnish

A varnish is a liquid coating that is applied to a printed surface. It adds a clear glossy, satin, matte, or neutral finish.

Below are a few types of varnishes to consider:

- Matte Varnish: Non-glossy smooth look.

- Gloss Varnish: sheen, glossy look.

- Silk or Satin Varnish: Not high gloss or matte, rather an in-between look.

- UV Varnish: An even more striking coating thanks to Ultraviolet technology.

- Spot UV Varnish: Applied to chosen areas of your print, highlighting certain elements of your design.

Foil

To achieve the silver or gold stamp, a layer of foil is fixed to a material through a heating process. This isn’t such a complicated process and getting print files ready for the process is similar to the process of UV spot printing.

Foil printing usually requires the supply of vector images or outlined fonts of what you would like to have stamped.

Die-Cut

Die-cut involves cutting shapes into paper or on paperboard by using a die. A die is used in printing or cutting for stamping, scoring, cutting, embossing, and debossing. Dies are usually custom made, but your printer will also have standard dies for rounded corners etc.

Letterpress

This is the oldest printing process. This method makes use of raised letters which are inked and then pressed onto the surface of the substrate to reproduce the design in reverse.

Metal type is usually used with this process but other options include stone blocks or wood. This is a popular technique for wedding invitations and this process is becoming increasingly popular with business card designs.

PROFESSIONAL GRAPHIC DESIGN AND PRINTING COMPANY SOUTH AFRICA

If you are looking to create a stand-out print marketing campaign using the top print techniques, speak to the Jetline printing and branding experts. We will guide you on the process to printing perfection, providing you with the ultimate end-result.

Contact your closest Jetline branch today!